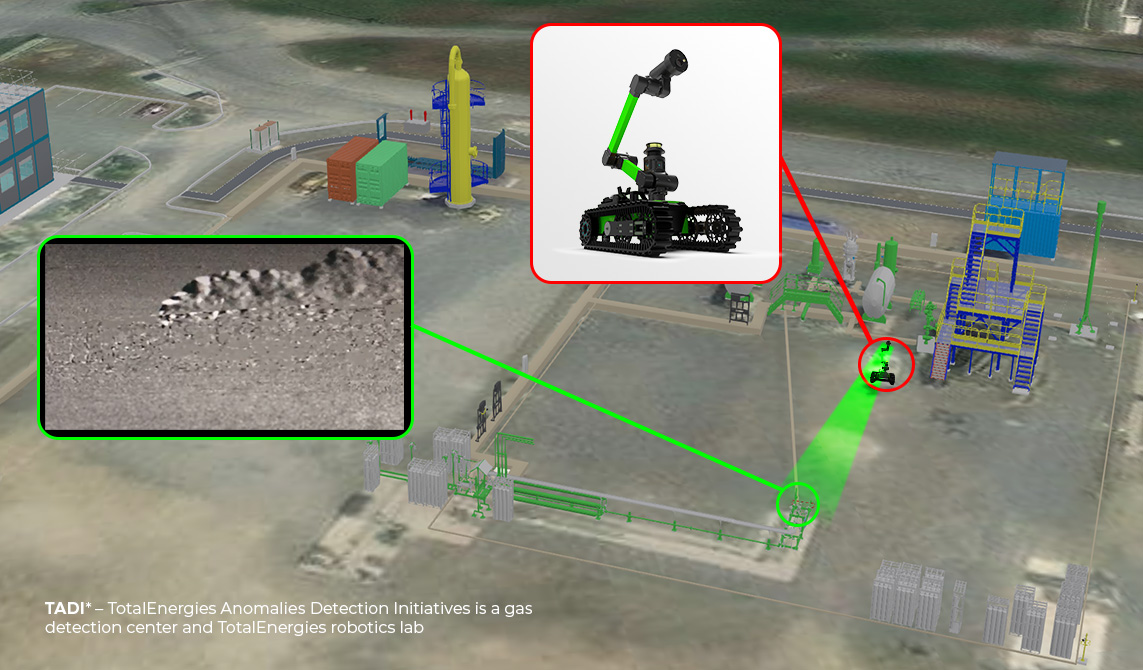

THE WORLD’S FIRST SPECIALIZED GAS DETECTION ROBOT.

Reliable and fast to identify the smallest gas leaks.

Stop methane leaks today.

Reducing emissions today.

The Inspector gasfinder is a reliable and fast tool to identify even the smallest gas leaks. By deploying the Taurob Inspector gasfinder, operators will be able to identify and monitor gas leaks earlier and apply corrective measures and maintenance efforts to reduce emissions.

Maintenance actions.

Supported by the expertise of Dietsmann (the leading independent Operation & Maintenance specialist for continuous-production plants in the energy industry), we offer the whole package, from identifying and prioritizing leaks to suggesting repair and maintenance actions. Furthermore, the Gasfinder’s flexible API can connect directly to client’s or third party analytics software.

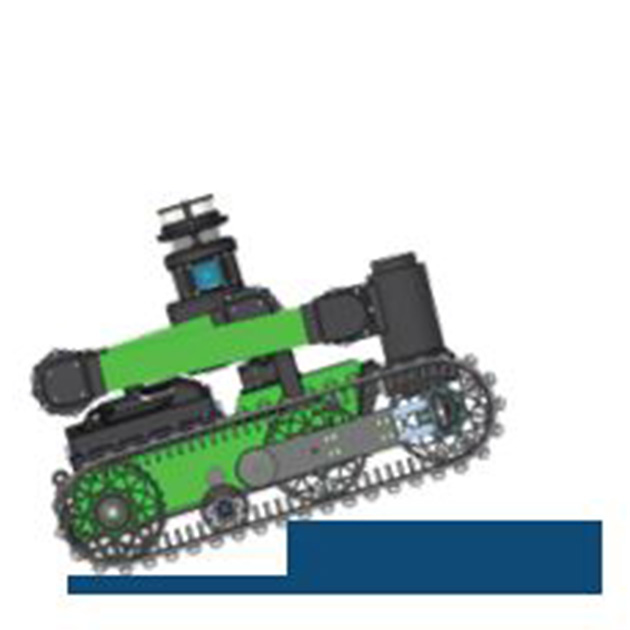

Beyond any obstacle.

■ Driving autonomously (including stair climbing up to 45°)

■ Movable arm for versatile point of views

■ LIDAR controlled (+ 360° images and video)

■ Patented caterpillar tracks for absolute safe driving

Everywhere. Every condition.

Built for the extreme, the Inspector gasfinder serves dutifully in harsh industrial environments, explosive atmospheres, adverse marine weather conditions and all sorts of terrain. Thanks to its PL-D certified safety controller, the Inspector gasfinder conforms with ATEX and IP67 standards.

Gas detection tasks.

■ Routine inspection

■ Leak detection

■ Data gathering

■ Location screening

■ Signalling anomalies

■ Emergency support

■ Methane detection

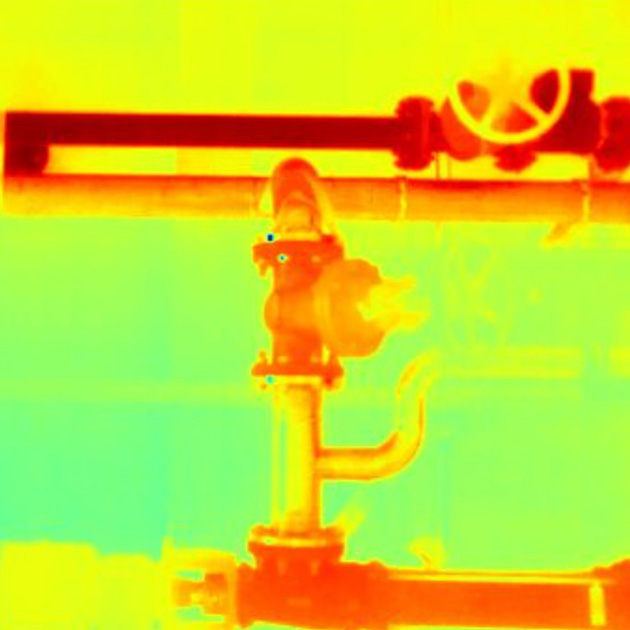

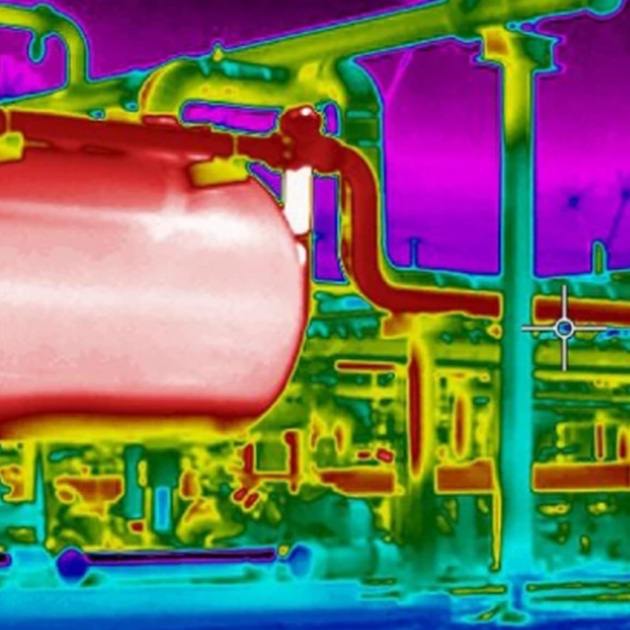

High end thermal camera

Top-tier gas detector

Long mission endurance

High and low temperatures

Software integration

Top of the line hardware.

The FLIR G300 is an optical gas imaging (OGI) camera that visualizes gas, to monitor installations in remote or hazardous areas for gas leaks and catch dangerous, costly hydrocarbon or volatile organic compound (VOC) leaks. OGI cameras are widely used in industrial settings, such as natural gas processing plants and offshore platforms.

The Taurob Gasfinder is also equipped with the Dräger X-am 8000 is one of the best gas-sniffer on the market. It can detect and analyse the smallest leak with up to 7 different type of toxic or inflammable gases.

*Case Study: detecting minuscule 2g/second methane leaks on the TADI site from 20 meters.