THE INSPECTOR ROBOT

The world´s toughest data gathering robot.

Robotized inspection and maintenance.

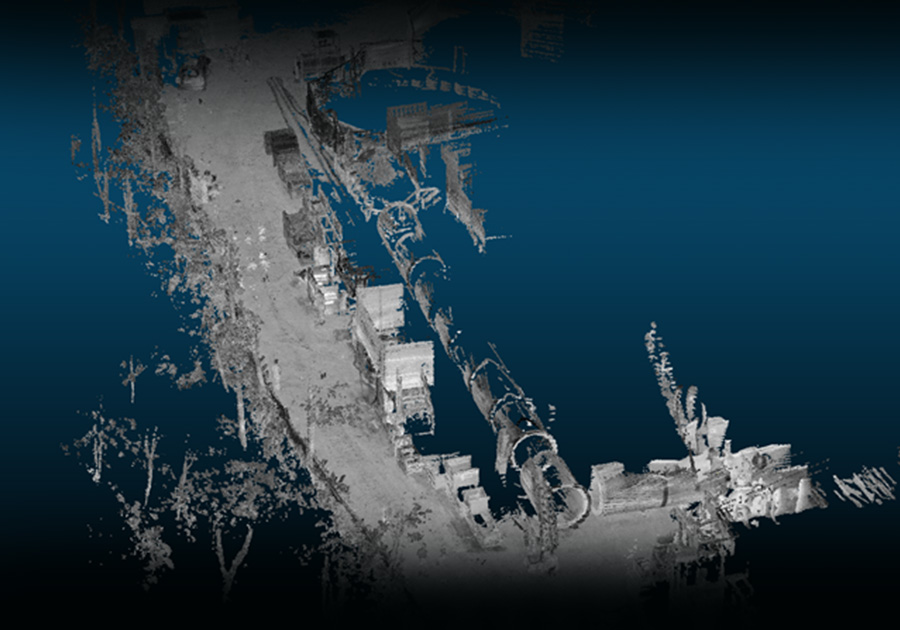

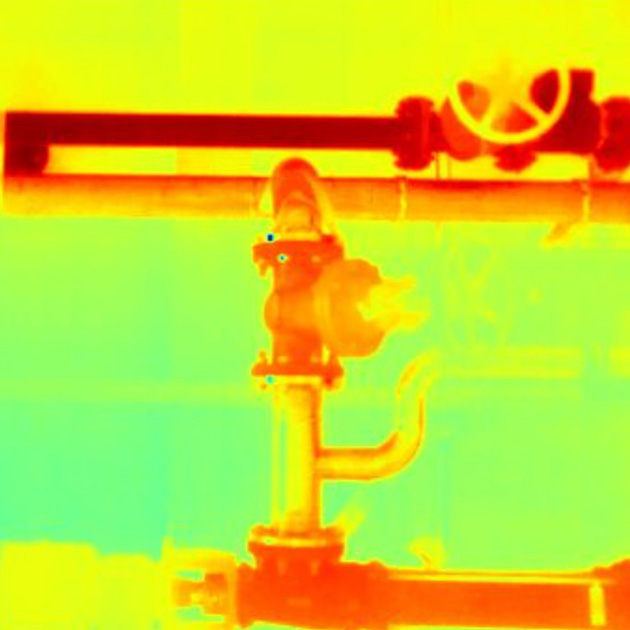

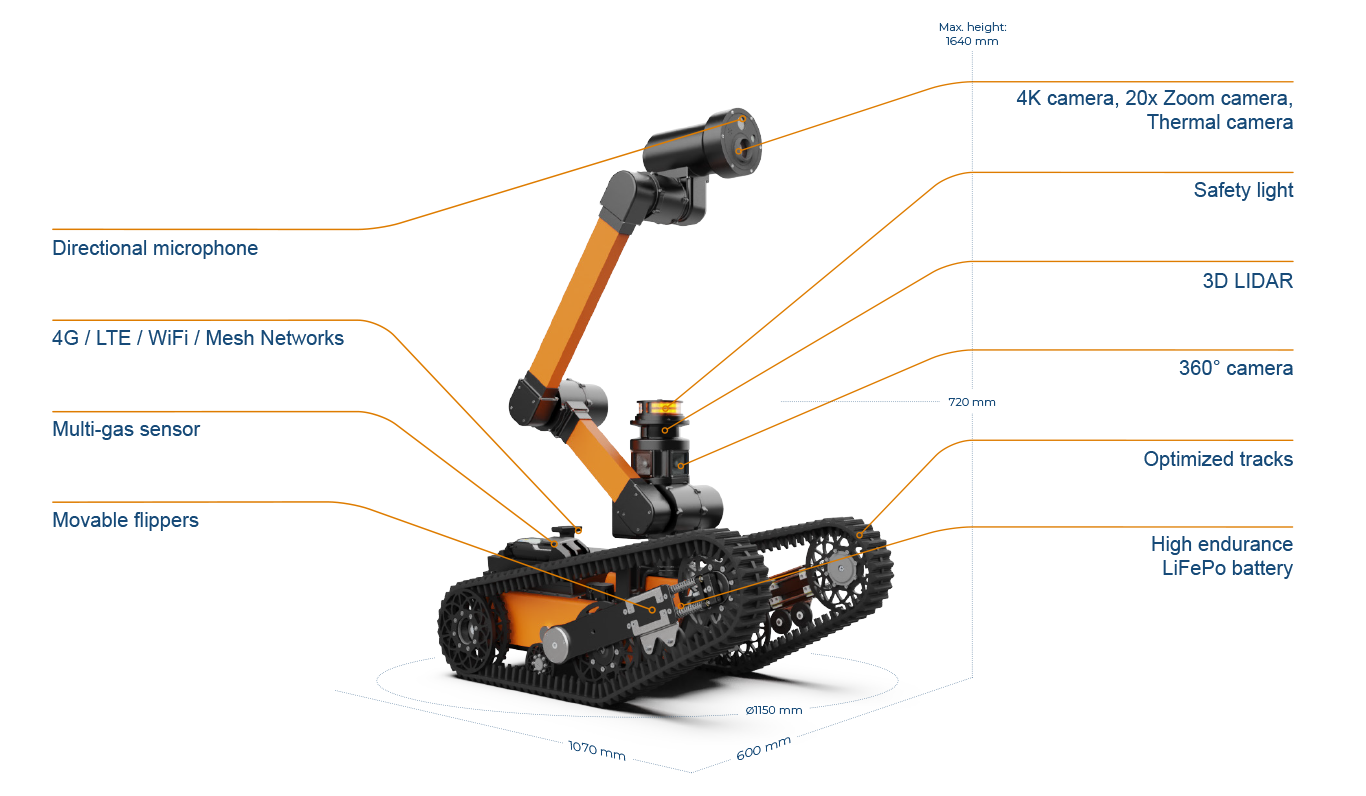

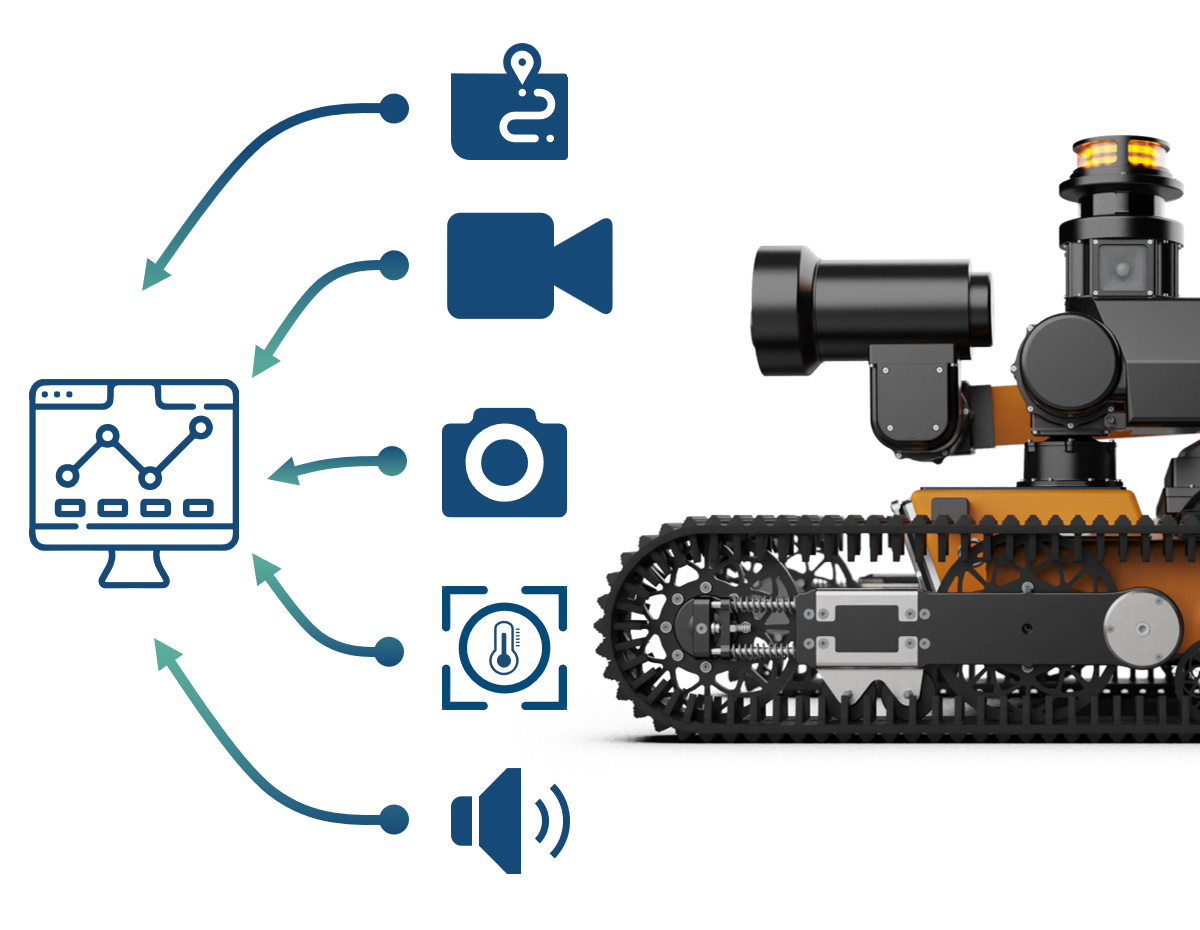

With the power of precision sensors, the Inspector excels in data collection with unparalleled versatility and objectivity, often surpassing human operators. It captures ultra-high-definition photos and videos, records sounds, identifies gas leaks through thermography, and surveys its surroundings with a 3D LIDAR scanner.

4 hour mission runtime

Natural born ATEX

Available within 1 month

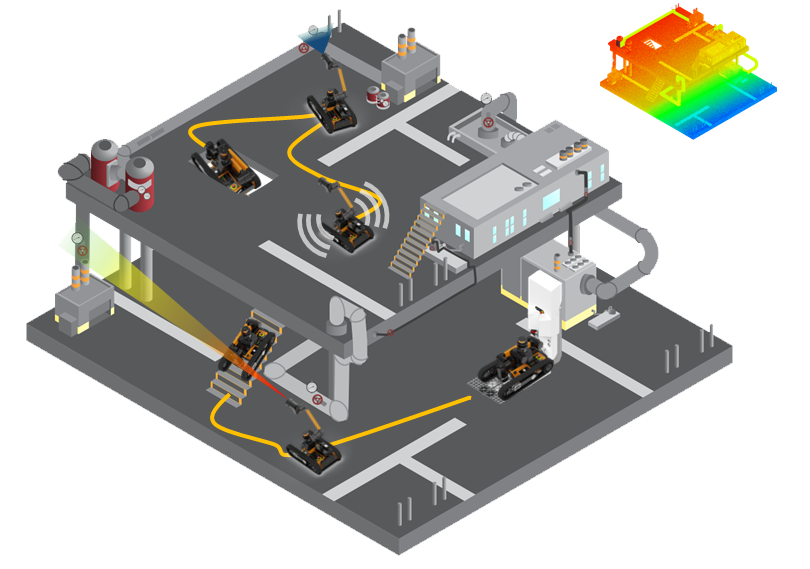

Ground robots are now a reality in the energy industry.

Ground robots are already a reality in the energy sector. They can navigate difficult terrain, operate in hazardous environments, collect data and lower emissions of operations. With advances in technology, the use of ground robots is expected to increase in the coming years.

credits: Taurob/TotalEnergies

SAFETY ABOVE ALL

INTEGRATION IN SOFTWARE SYSTEMS

HUMAN-LIKE PERSPECTIVE

HIGH MISSION ENDURANCE

TACKLING MULTIPLE FLOORS

HIGH RELIABILITY AND AVAILABILITY

FOR EXPLOSIVE ENVIRONMENT

INSPECTION AND MAINTENANCE EXPERTISE

Climbing industrial stairs up to 45°

Long endurance and fast charging

High human perspective with its long arm

High and low temps (-20C° / +60C°)

ATEX CERTIFIED DOCKING

Automatic battery charging and pressurization in ATEX Zone.

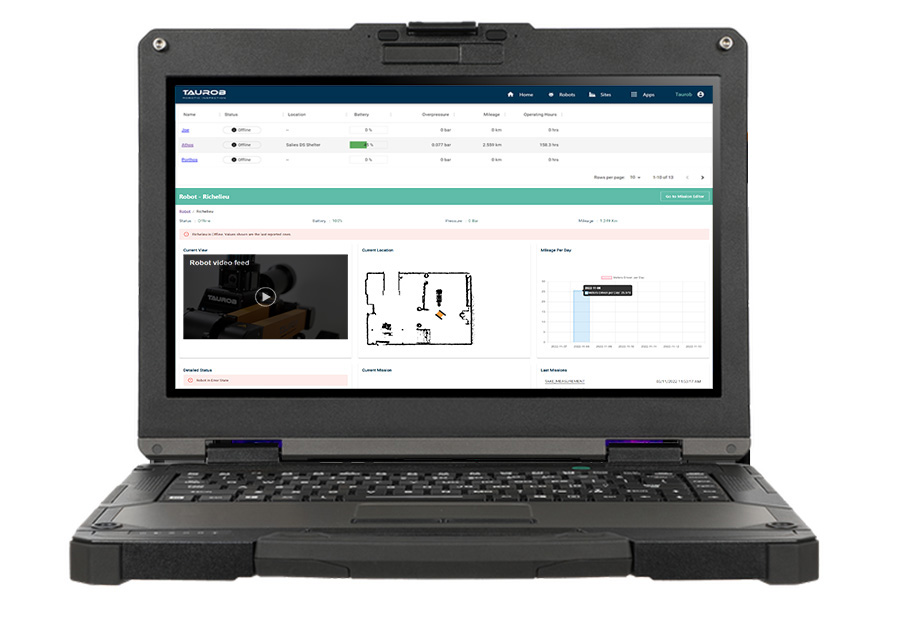

EasyDrive and EasyMissioN WEB APP

Remote mission settings via app over WiFi, LTE or 4G connection.

Third party software integration

Easily connects and interacts with specialized software.

Integration in software systems

Human-like perspective

Fast charging in ATEX zone

High mission endurance

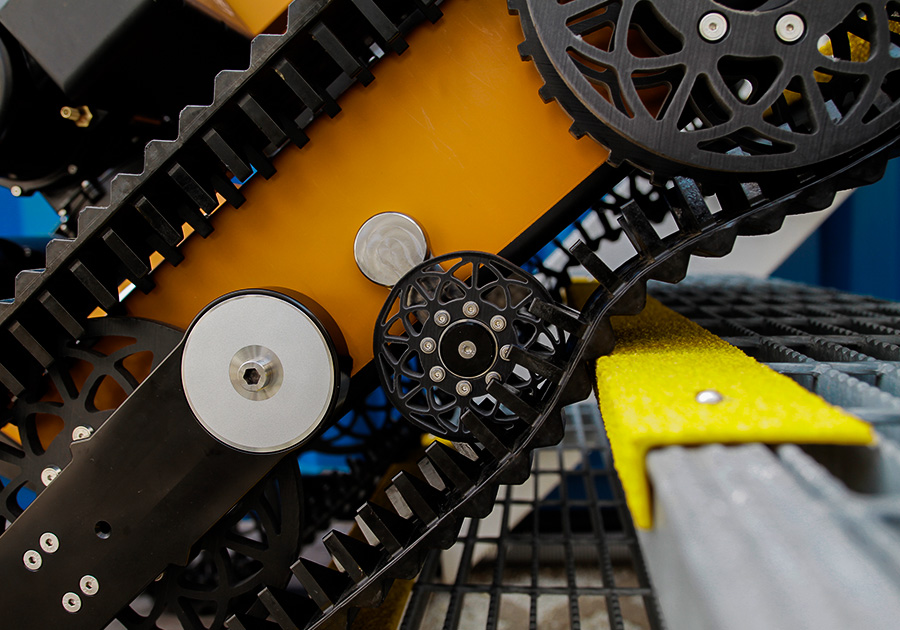

Advanced tracks

ATEX certified

+60°/-20° C operational temperatures

Inspection maintenance expertise

ATEX zone 1 docking

Tackling multiple floors

Everywhere. Every condition.

Built for the extreme, the Inspector serves dutifully in harsh industrial environments, explosive atmospheres, adverse weather conditions and all sorts of terrain.

Software agnostic by design.

Taurob Inspector is designed to ensure seamless integration into existing IT/OT environments. From edge systems to enterprise software, without vendor lock-in.

Seamless integration with any 3rd party system, trusted security and on-premises installations thanks to our flexible API and working with specialized partners.

We design and build our robots with flexibility at their core. Customers can operate them using either our in-house software solutions (EasyDriveWeb, EasyMission and Admiralty) to navigate, execute autonomous missions and coordinate robot fleets or by using their dedicated platforms.

We also provide a robust API that enables seamless integration with third-party software by Rockwell Automation/Kalypso, Energy Robotics, Yokogawa, DroneDeploy and more. This dual approach ensures maximum adaptability and smooth system integration across diverse operational environments.

Application in many industries.

Oil&Gas

Power Generation

Chemical

Mining

Surveillance

Emergency Response

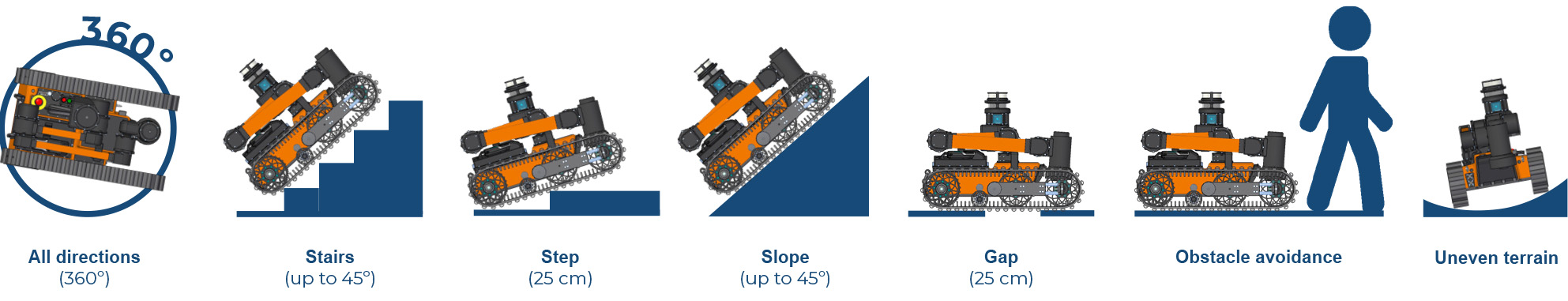

Beyond any obstacle.

- Autonomous drive mode

- Stair climbing up to 45°

- Obstacle recognition and avoidance system

- Gaps, steps and uneven surfaces overcoming

- Movable long arm for versatile point of views

- Patented caterpillar tracks for absolute safe driving

Advanced data integration.

The Inspector’s software enables real-time data transmission to cloud or on-premise servers, facilitating mission and goal optimization. With its flexible API, it connects directly to a client’s digital twin or easily integrates with third-party analytics tools for advanced data analysis.

Combined knowledge in collaboration with:

Specifications.

Specs subject to change.

Get the Inspector.

- Level 1 maintenance

- Gas detection

- Site surveying

- Corrosion detection

- Dial-gauge reading

- Valve positions

- Fill level reading

- Pump noise analysis

- Fan belt sound analysis

- Emergency response