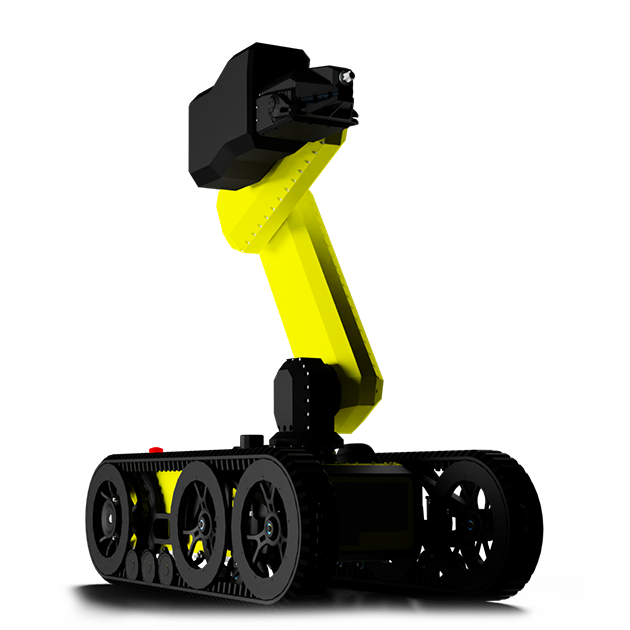

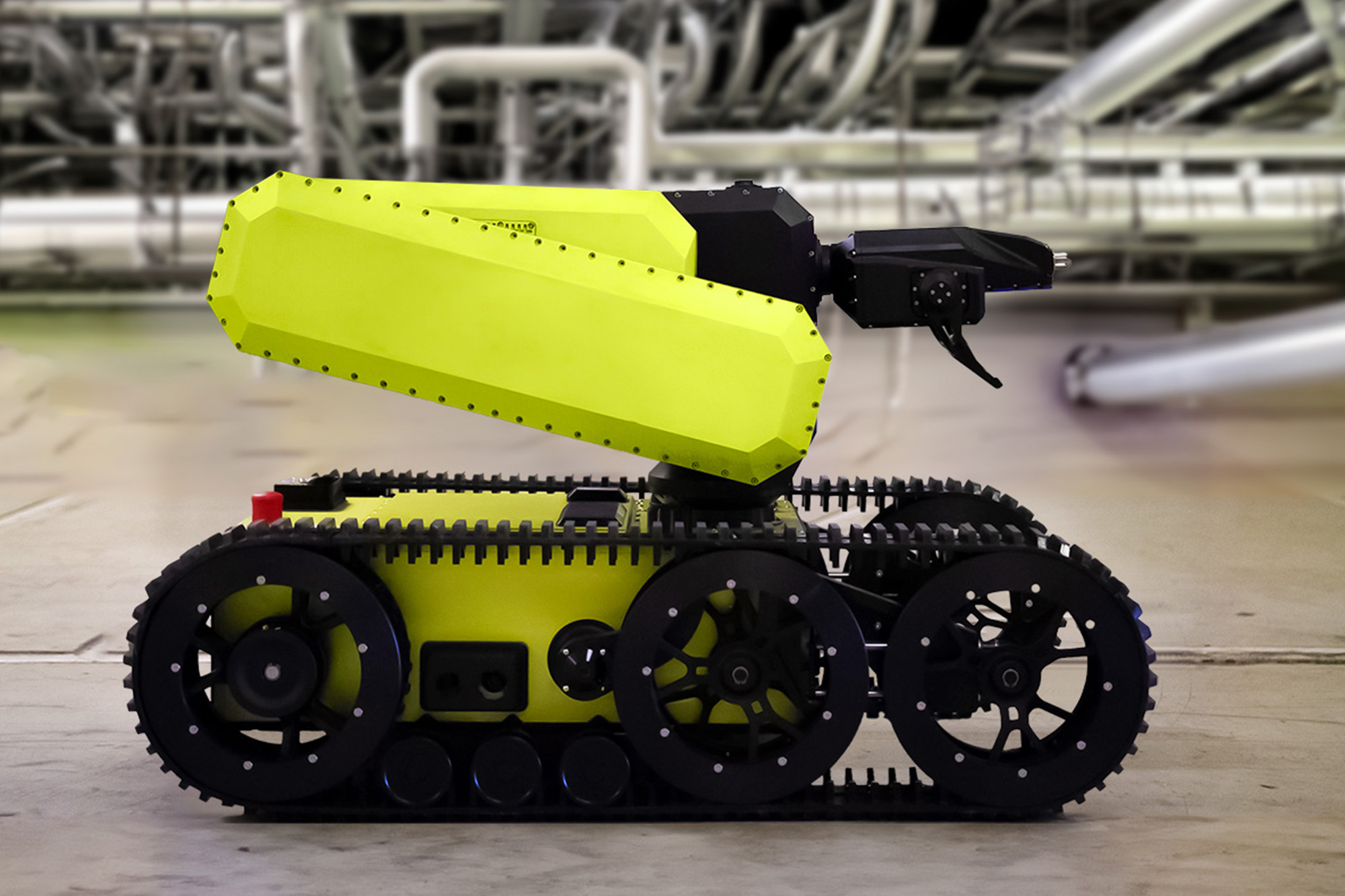

THE TAUROB OPERATOR.

The power of interacting with equipment.

COMING SOON

Revolutionizing industrial operations.

The Operator robot is setting a new standard in the Energy industry.

It can be remotely controlled or be completely autonomous in interacting with industrial machinery like valves and dial gauges, lifting and transporting heavy components up to 75 kg and inspecting through different sensors like LIDAR system, thermal camera, 360° view and microphone.

High-temperature resilience and heavy lifting.

Engineered to withstand extreme environmental conditions of up to 60°C, the Taurob Operator’s high-performance arm can also lift an incredible 75 kg.

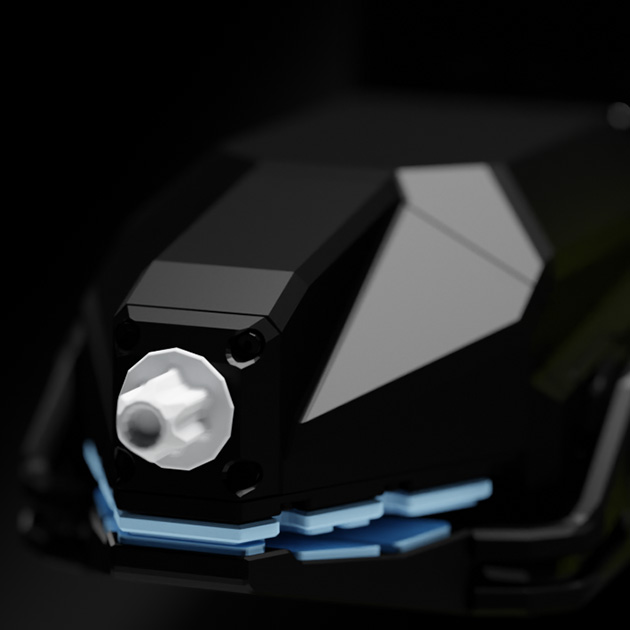

Its robust end-effector delivers torque of up to 150 Nm and a gripping force of more than 100 N.

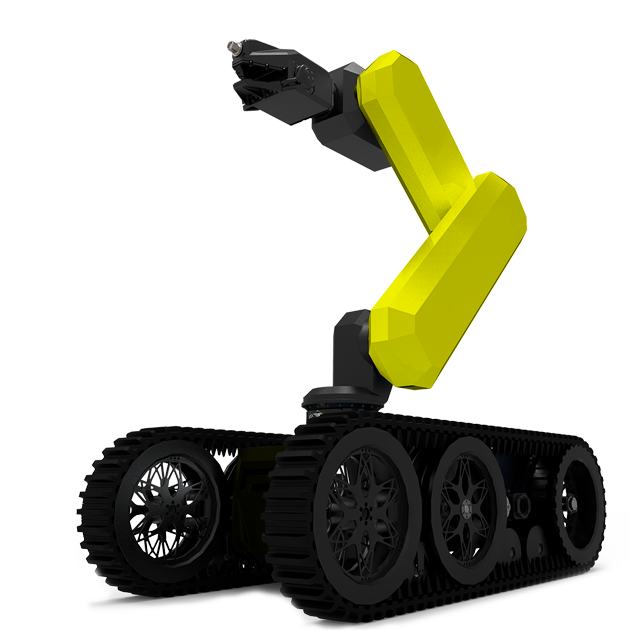

Arm with 5 DOF

It lifts up to 75 kg

Gripping force 100N

Max. torque ~150Nm

Certified robot for broad application in the energy industry.

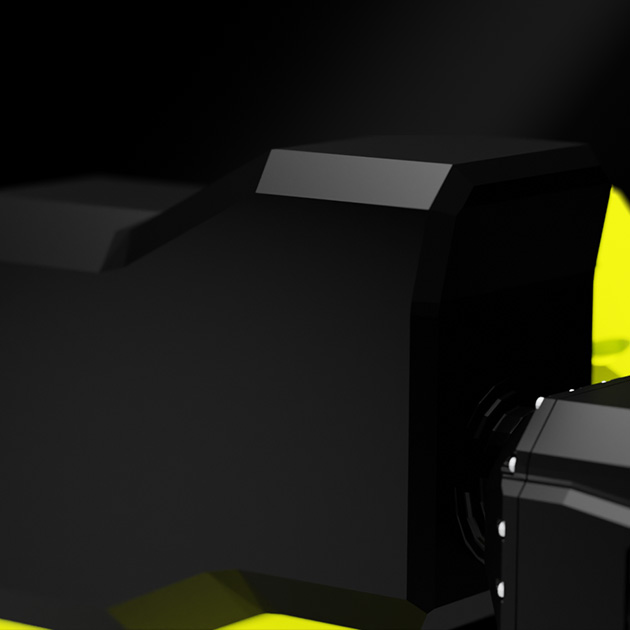

With options for remote control or full autonomy, the Taurob Operator is a versatile solution. Beyond equipment manipulation, it can also perform inspection and data collection tasks, featuring advanced sensors such as LIDAR, thermal and depth cameras, as well as 360° visibility and audio capture capabilities.

Combined knowledge in collaboration with:

An industry game-changer.

The Operator sets a new benchmark in the industry by seamlessly interacting with industrial machinery, effortlessly handling valves, dial-gauges, and other heavy-duty tasks. Furthermore, the Operator boasts impressive strength, by lifting and transporting heavy components weighing up to 75 kg.

Specifications.

| General | |

| Dimensions | 1200 x 600 x 800 mm |

| Weight | 145 kg |

| Speed | 0,45 m/sec |

| Battery | Running 4 h Charging 4 h |

| Sensors | |

| Camera | 4x 2K for 360º view 1x 4K in arm |

| Navigation | 2x 3D LIDAR |

| Audio | Microphone |

| Gas | Dräger X-am 8000 |

| Safety | |

| Monitoring | SIL2, PL-D Onboard Safety Controller |

| Environment | |

| Climate | -20º C to +60º C IP67 |

| Surface | Grated Floors Concrete, Grass Gravel, Sand Ramps Stairs (up to 45º) |

| Arm | |

| Arm length | 5 DOF 1400 mm perpendicular 1800 mm vertical |

| End Effector | Gripping force over 100 N Max. torque ~150 Nm Able to handle customized tools |

| Max. Lifting | Up to 75 kg in near field Up to 30 kg outstretched |

| Site requirements | |

| Connection | 3G/4G or WiFi |

| Power | 100 – 240 VAC 50/60 Hz max 1.3 A |

| Purging gas | Nitrogen |

| Teleoperation |

| First Eyes on Scene |

| Fast Incident Response |

| Manual Inspection |

| Spill Monitoring |

| Site Surveying |

| Autonomous inspection |

| Mapping and Teach-in of POIs |

| Data Gathering Missions |

| Anomaly Detection |

| Obstacle Detection |

| Level Change / Stair Climbing |

| Data acquisition |

| 4K Photos |

| 4K Videos |

| Audio Clips |

| Point Clouds |

| Gas Sensor Data |

| Data processing |

| In Cloud or on Edge (local server) |

| API for Client System integration |

| 3rd party apps: Dial Gauges, etc. |

| 360º Videos |

| Street-view |

Specs subject to change.

Use cases.

■ Level 1 Maintenance

■ Gas detection

■ Site surveying

■ Corrosion detection

■ Dial-gauge reading

■ Valve manipulation

■ Fill level reading

■ Pump noise analysis

■ Fan belt sound analysis

■ Emergency response

The ARGOS Joint Industry Project.

Our development partners: