ROBOT DEPLOYMENT.

Reduce emissions

and maintenance costs with robotics.

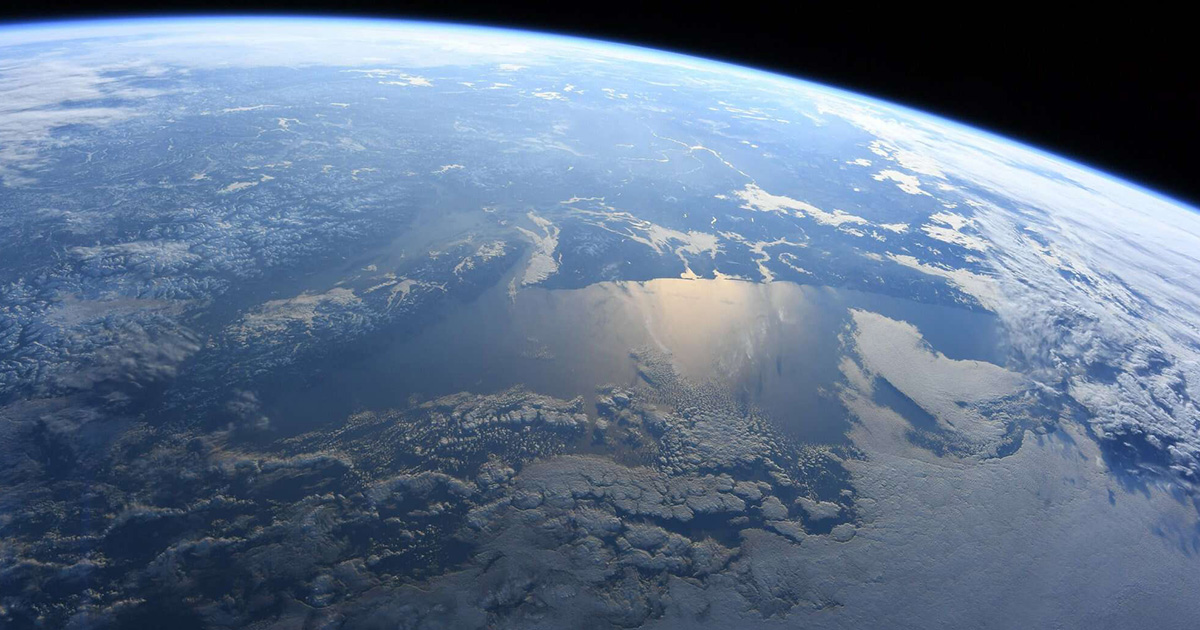

credits: TotalEnergies

Let the robots do the work.

In the modern industrial landscape, companies are constantly looking for ways to streamline operations and improve efficiency. One solution that has proven effective is the deployment of robots for routine inspections and operations.

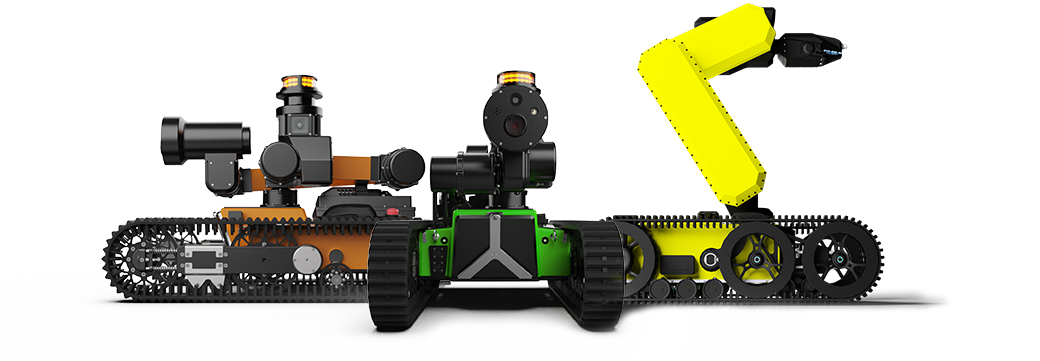

Our robots are designed to meet your specific on-site needs, from simple remote control to advanced autonomous capabilities in order to optimize human labour and improve work safety.

Reliability, toughness, flexibility and cutting-edge tech.

Our robots are built to endure the most hazardous situations, equipped with advanced safety features and rugged construction. Whether it’s withstanding harsh terrain conditions or extreme temperatures, our robots are engineered to persevere on their missions.

Taurob robots possess remarkable flexibility, capable of traversing various obstacles, including climbing stairs and access areas designed for humans thanks to a long-arm.

With our advanced technology, we empower industries to enhance productivity, improve safety, data collection and help reduce emissions.

Leaner construction of assets.

By using robots, the size and complexity of future installations can be reduced (e.g. no living quarters) which positively affects construction emissions of new platforms.

Reduced gas leakage.

The Taurob Inspector and Gasfinder can locate and quantify emissions from oil&gas operations and track deterioration over time on autonomous missions in a repetitive and punctual fashion.

Unmanned facilities, less logistics.

Eliminating human

transportation and logistics

significantly reduces CO2

emissions.

Less cost, less risk, less emissions.

With streamlined operations and cost-efficiency while minimizing logistical complexities and personnel risk, Taurob robots gather abundant data and contribute to reduce emissions for a more sustainable site.

Reducing emissions to the environment.

Optimizing production costs & asset uptime.

Inspecting, gathering and analysing data 24/7.

Taking men out of harm’s way & ensure the highest standards of HSE.

Images credits: TotalEnergies

More efficiency, more data, more sustainable.

Streamline your operations.

A cost saving solution.

Taurob’s robots help to reduce the need for manual labour, freeing up employees for more valuable tasks. By working in harsh environments and gathering valuable data, robots can provide a cost-saving and efficient solution for industrial inspections.

Leaks finding.

Gas leakage minimization.

Localization and quantification of small leaks, imperceptible by humans, from oil&gas operations and deterioration tracking over time.

Smooth system integration.

Software agnostic.

A simple API that enables a smooth integration with any system to seamlessly connect our software to your existing systems, including ERPs, and more. This integration allows for a more efficient workflow.

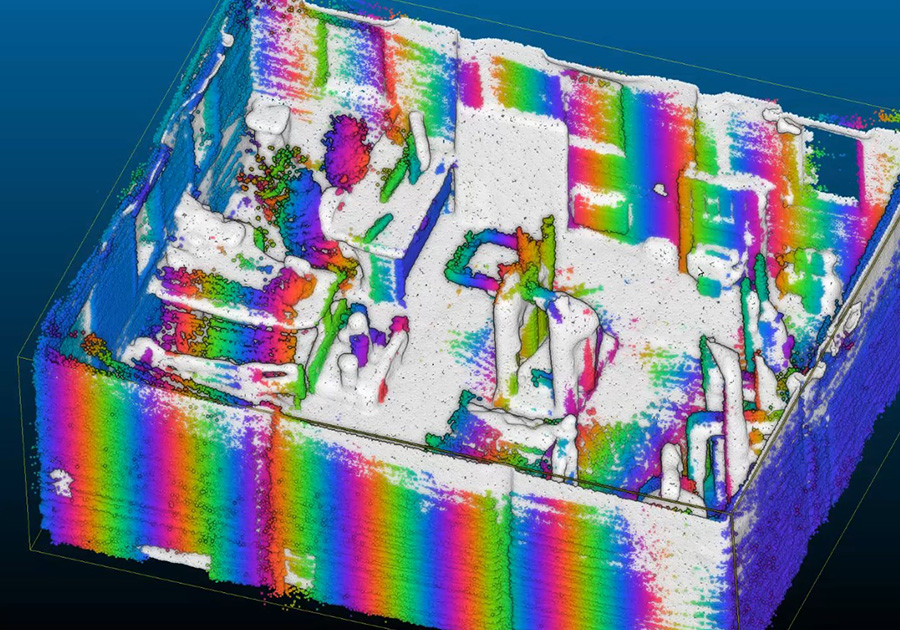

Mapping and data analysis.

Moving intelligence.

Maximize the efficiency and accuracy of your industrial inspections with robots capable of mapping and traversing the site while collecting data. Our robots can navigate hazardous and hard-to-reach areas, providing a complete and in-depth view of your facilities.

No helicopter flights.

Reduced transportation.

Limited transportation and logistics of workers to and from off-shore platforms, leading to a reduction of up to 6.450 tonnes CO2-eq. yearly on a single FPSO unit, calculated over 20 years.

Less installations.

Way to NetZero.

No need for staff´s living quarters in new facilities (e.g. no living quarters), with a consequent reduction of emissions due to energy intensive processes like steel production.

Taurob robots’ unique features.

Integration in software systems

Human-like perspective

High mission endurance

Extreme temperatures

Inspection and maintenance expertise

For explosive environment

Tackling multiple floors

All-round tracks

Integration in software systems

Human-like perspective

High mission endurance

Extreme temperatures

Inspection and maintenance expertise

For explosive environment

Tackling multiple floors

All-round tracks

Thriving in high-risk environments.

Taurob robots are engineered to withstand extreme conditions, enabling them to excel in harsh industrial environments, explosive atmospheres, and adverse weather conditions, suitable for a variety of industries.

Oil&Gas

Power Generation

Chemical

Mining

Surveillance

Emergency Response

Robotized industrial operations.

Taurob designs, manufactures and commercialize autonomous robots for operation, inspection and maintenance of heavy industrial plants in order to optimise production costs, asset uptime, reduce emissions and to ensure the highest standards of HSEQ management.